Fraunhofer IPMS develops Breakthrough Chip for Robust, Portable pH Measurements

Fraunhofer Institute for Photonic Microsystems IPMS has achieved a significant breakthrough in pH measurement technology, developing a durable chip-based solution that replaces traditional error-prone reference electrodes.

RELATED: Fraunhofer IPMS develops AI-powered hyperspectral camera for real-time industrial analysis

The new technology enables pH measurements that are significantly more robust, simple, and reliable than conventional methods. The chip can be stored dry, is pressure-resistant, and can be easily integrated into compact devices—addressing long-standing challenges in chemical sensor technology.

Initial test kits are already available for rapid deployment across medical, biological, agricultural, and environmental applications.

The Problem with Traditional pH Measurement

Precise pH measurement has historically been a major challenge in chemical sensor technology. Conventional silver/silver chloride/potassium chloride electrodes, while providing a stable reference potential, are highly prone to errors.

Common failure points include:

- Changes in electrolyte concentration

- Clogged or dried-out membranes

- Drift due to concentration changes

- Contamination of the measurement solution

While pH-sensitive glass electrodes have already been successfully replaced by robust chips called ion-sensitive field-effect transistors (ISFETs) , replacing the sensitive reference electrode has remained elusive—until now.

The Fraunhofer Solution: REFET Technology

Researchers at Fraunhofer IPMS have now succeeded in replacing the sensitive reference electrode with a reference ISFET (REFET) .

Olaf Hild

“Our ISFETs are reliable, stable, and durable. They overcome common problems of conventional reference electrodes, such as clogged or charged diaphragms, drift due to concentration changes, and contamination of the measurement solution,” explains Dr. Olaf Hild, Division Director of the Chemical Sensors and Systems department at Fraunhofer IPMS.

This breakthrough makes the technology particularly suitable for mobile or integrated measurement systems, where reliability and compactness are essential.

How It Works

The new technology uses a second ISFET alongside a standard pH ISFET, replacing the traditional reference electrode:

- The reference ISFET has a significantly lower pH slope of 20 mV/pH at 25°C, compared to the standard 59 mV/pH predicted by the Nernst equation

- Both ISFETs are coated with thin layers of niobium pentoxide (Nb₂O₅) or tantalum pentoxide (Ta₂O₅) , providing high stability, ease of handling, and excellent storage properties

- The two ISFETs operate together via an auxiliary electrode to reliably calculate the pH value from measured electrical signals

Initially, pH measurement will be possible in the range of approximately pH 4 to pH 8, which meets the typical requirements for many applications in biology, medicine, agriculture, and environmental monitoring.

Current Specifications and Future Development

Currently, the technology uses two 5 mm × 5 mm chips required for proper wetting, though size can be reduced upon customer request. Future plans include:

- Combining both functions into a single chip of the same size

- Integrating temperature measurement directly onto the chip

- Expanding the pH range through improved sensor layers

- Reducing REFET sensor drift

- Compensating drift through advanced control electronics

*”Long-term measurements after a 2- or 3-point calibration require precise control of sensor drift. The drift can be compensated for with the help of the control electronics,”* explains electronics developer Hans-Georg Dallmann.

A Concept Whose Time Has Come

Dr. Hild acknowledges that the ISFET-REFET concept is not new:

*”Unfortunately, we did not develop the ISFET-REFET concept. It was created in the 1980s by Professor Piet Bergveld, the inventor of the ISFET, and his colleagues. However, the concept has so far not been adopted commercially.”*

Fraunhofer IPMS aims to change that by delivering practical, commercially viable components that make the technology accessible for widespread use.

Available Now for Testing

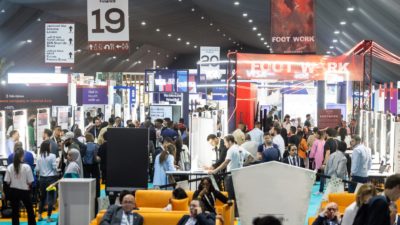

Test kits are already available for organizations eager to explore the technology’s potential. Fraunhofer IPMS will showcase the new solution at Analytica 2026 (Hall 3, Booth 312), where attendees can see the technology firsthand.

“Although much work still lies ahead, we are pleased to already offer test kits and to present them to the professional audience at Analytica 2026,” Hild concludes.

Individual appointments at the conference can be arranged in advance via the Fraunhofer IPMS website.