In all industrial zones of Africa – from Zambia’s copper mines to Nigeria’s oil rigs – an unseen partner is paving the way for safer and more efficient industries. As economies invest in mining, manufacturing and energy infrastructure, the challenge of safety and operational discipline is growing. Artificial Intelligence (AI), once confined to research labs, is now coming to the frontline to predict risks, limit accidents, and improve efficiency of the workforce.

RELATED: Vertiv to spotlight AI-ready infrastructure and next-gen solutions at AfricaCom 2025

For many decades, industrial safety has relied on human vigilance and manual reporting. Now, predictive algorithms, real-time analytics, and computer vision are transforming those instincts into measurable insights – from safety scores that quantify performance to hazard heatmaps that reveal hidden risks. These tools are building a culture where prevention takes precedence over correction. For Africa’s fast-evolving heavy industries, AI is not just another digital upgrade; it is redefining the rhythm of work and synchronizing human expertise with data-driven foresight.

Inside Africa’s Heavy Industries

Heavy industries such as mining, oil and gas, construction, and manufacturing remain central to Africa’s economy, generating export revenues and supporting millions of livelihoods. However, much of this activity still relies on fragmented safety oversight and reactive monitoring systems. When something goes wrong, like a malfunctioning conveyor, a gas leak, or a scaffold collapse, response times often hinge on ‘who notices first’. Paper-based reporting and delayed escalation remain the norm, making real-time safety management an ongoing challenge.

Recent studies highlight the cost of this gap. The International Council on Mining and Metals (ICMM) recorded 24 workplace fatalities across Africa, the highest regional share among member companies worldwide, with a fatality frequency rate of 0.024 per million hours worked. It further uncovered that a majority of these incidents arose from mobile equipment and transportation hazards, indicating persistent blind spots in hazard detection and intervention.

As industrial activities increase to meet the growing demand for energy and raw materials, safety lapses and productivity losses continue to impose both human and financial risks. This risk is further exaggerated due to infrastructure limitations, skills labour shortages, and uneven safety compliance. As economic stakes climb, safety failures carry consequences that extend beyond injuries – they disrupt national productivity and social stability. It is for this reason that industry leaders are now searching for new visibility tools like hazard heatmaps, real-time alerts, and predictive analytics that can transform Africa’s most hazardous workplaces into environments guided by continuous insight rather than delayed reaction.

The AI Inflection Point

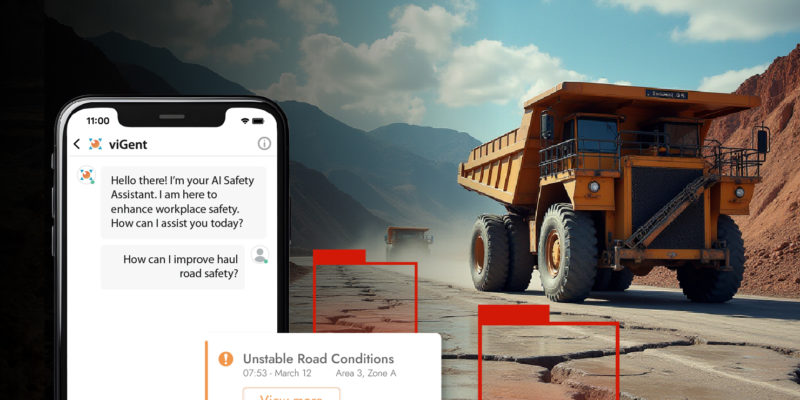

Africa’s heavy industries are reaching an AI-driven inflection point, where digital intelligence is being embedded into safety-critical operations. AI is now wiring itself into the daily rhythm of mines, factories, and refineries. Computer vision systems are using AI CCTV to monitor unsafe behaviour. IoT sensors are providing real-time readings of heavy equipment, monitoring temperatures, pressures and other performance metrics. Predictive analytics models allow organisations to predict risks in advance, and trigger early warnings of equipment fatigue when certain metrics reach a threshold level.

In Southern Africa, for instance, gold and platinum mines have begun monitoring the mine’s underground seismic sensors and vibration data in real-time, to predict rockfall risk. This enabled proactive evacuation and equipment shutdowns before incidents occurred. In the same region, a manganese processing plant in the Northern Cape used AI-enabled optimisation; creating real-time digital twin model to aggregate a multitude of data inputs from sensors, including abnormal vibration in pump circuits, in order to perform maintenance prior to breakdown and increase operating time.

Similarly, in Nigeria, a large cement factory implemented a sensor network across its kilns, crushers and conveyors to feed into AI models that detected temperature or vibration anomalies, allowing predictive maintenance to occur weeks ahead of breakdowns.

Beyond asset performance, the next frontier for AI in industrial safety lies in decoding human behaviour, i.e., monitoring actions, interactions, and emotional cues that influence the dynamics of risks on-site. For example, in Ghana, a major mining site downsized workplace altercations by 62%, following the deployment of AI-powered Fighting and Violence Detection technology. It analysed CCTV feeds in real-time and alerted supervisors to early signs of aggression. Within three months, the operation recorded fewer disruptions, enhanced morale, and significant stabilization of operations — demonstrating how behavioural analytics can enhance both safety and productivity.

AI and the Sustainability Shift

While AI strengthens Africa’s approach to occupational safety, it is also transforming the understanding and practice of sustainability. Intelligent energy controls are minimizing idle power consumption in mining and cement plants; predictive systems are reducing water wastage in processing lines; and digital twins allow operators to run production scenarios before committing real resources. These developments are consistent with Africa’s Green Industrialization Strategy and the increasing demand for transparent ESG reporting throughout the continent.

“AI is not only automating industry, it’s teaching industries how to sustain themselves,” says Gary Ng, CEO of viAct. “When every process becomes measurable, sustainability stops being an aspiration and starts becoming operational.”

By embedding intelligence at the core of production, Africa’s heavy industries are laying the foundation for long-term, low-impact growth.

The Ethics of Industrial AI

As AI systems become integral to Africa’s industrial operations, new ethical and operational challenges are also surfacing. Data scarcity, inconsistent connectivity, and costly digital infrastructure continue to deaccelerate implementation. Limited access to skilled AI engineers remains yet another challenge. Nonetheless, the more consequential issue at stake is governance — how safety, surveillance, and performance data are collected, processed, and stored. Vision-based monitoring and predictive analytics gaining momentum, with privacy, consent, and accountability increasingly becoming part of the conversation of responsible innovation.

But these are growing pains, not impediments. Emerging solutions such as on-prem and edge processing are allowing industries to analyse data locally and thereby reduce exposure and dependency on external servers. These trends, combined with emerging AI ethics frameworks and regional data protection legislations, are shaping a uniquely African model of responsible innovation. The journey is complex and a long one, but it is a journey that progresses steadily from experimentation to institutional trust in AI systems.

The Road Ahead for Industrial AI in Africa

Africa’s next phase of industrial growth will be defined not by scale, but by intelligence. From once operating in isolation, machines are now a part of a learning network that sees, predicts, and adapts. Each sensor, algorithm, and digital twin adds a new layer of awareness to operations previously defined by instinct. The outcome is a more responsive, resilient, and human-centric industrial ecosystem.

However, this revolution cannot be carried forward by technology alone. The real inflection point lies in leadership – in the vision to deploy AI ethically, train the workforce inclusively, and embed sustainability into every algorithmic decision.

Africa’s intelligent industries are no longer on the horizon – they are in motion, defining a future where progress is predictive, sustainable, and profoundly human.